At TecTriu, we are committed to providing sustainable solutions for plastic manufacturing. These solutions seamlessly align with environmental goals and the latest industry advancements. Furthermore, this article explores critical aspects of sustainability in plastic production. Specifically, it examines thermoplastic and thermoset molding processes, tool design innovations, and the integration of digital technologies.

Sustainability in Thermoplastic Molding

- Material Selection: The use of biodegradable plastics, recycled polymers, and bio-based resins has gained importance. These materials reduce dependency on fossil fuels and minimize waste.

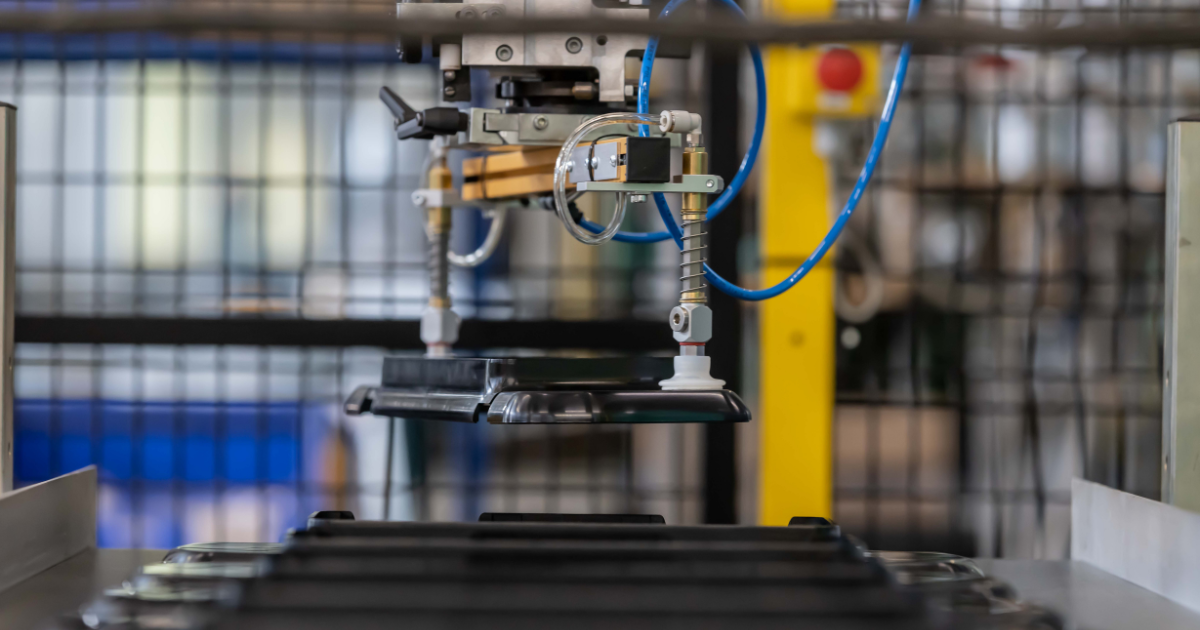

- Energy Efficiency: Advanced machinery and automation reduce energy consumption. The usage of properly sized equipment helps lower energy impacts.

At TecTriu, we adopt energy-efficient technologies and sustainable materials for thermoplastic molding.

Tooling Design

Tooling design plays a crucial role in achieving sustainability goals in plastic production.

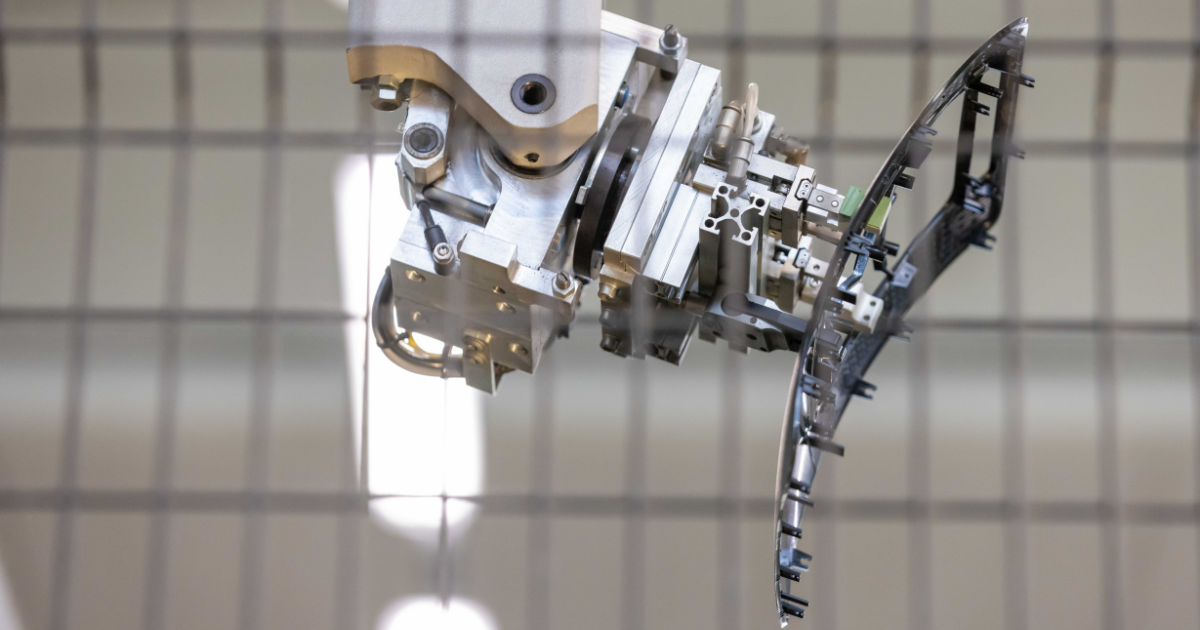

- Lightweight Tools: Using lightweight materials for tools improves energy efficiency by reducing the energy required for handling and processing.

- Optimized Design: Properly designed tools aim to eliminate or minimize injection runners. Reduced or absent injection runners decrease the amount of raw material needing recovery and speed up molding cycles, leading to lower energy impact.

- Digital Twins: Simulation technologies enable manufacturers to test and optimize tool designs virtually before production, reducing errors and resource consumption.

Sustainability in Thermoset Molding

Thermoset molding, often used in high-performance applications, presents both unique challenges and opportunities for sustainability. Unlike thermoplastics, thermoset materials cannot be melted and re-molded, which makes waste reduction particularly critical. To address these challenges, TecTriu has pioneered an innovative project called Xtrim.

Specifically, Xtrim focuses on recycling and reinserting part of the recycled material into new thermoset resins. As a result, it achieves up to 20% recycled content without compromising material performance. Furthermore, this groundbreaking solution ensures that thermoset materials can align with circular economy principles. Consequently, it significantly reduces waste and minimizes environmental impact.

Key strategies in sustainable thermoset molding include:

- Resin Innovations: Through projects like Xtrim, TecTriu is driving the development of thermoset materials that incorporate recycled content while maintaining strength, durability, and functionality.

- Process Optimization: we focus on precision manufacturing and material efficiency to minimize waste.

- Lifecycle Management: TecTriu prioritizes end-of-life solutions, enabling industries to reclaim fibers, recycle components, and extend product lifecycles, promoting circular sustainability.

TecTriu provides expertise in sustainable thermoset molding, helping businesses implement innovative solutions to reduce their environmental footprint and support long-term sustainability goals.

Design to Sustainability and Digitalization

The future of plastic manufacturing lies at the intersection of sustainability and digitalization, offering new opportunities for innovation and growth. By seamlessly integrating digital tools and sustainable design principles, businesses can achieve smarter, greener, and more efficient operations. Furthermore, key advancements driving this transformation include:

- Eco-Conscious Product Design: Incorporating sustainable materials, modular components, and designs that promote recyclability are essential for reducing waste throughout a product’s lifecycle.

- Digital Transformation: The use of Industry 4.0 technologies—such as IoT, AI, and data analytics—optimizes processes, reduces energy usage, and minimizes material waste.

- Lifecycle Analysis (LCA): Digital tools enable comprehensive analysis of environmental impact across the entire value chain, driving informed decisions for sustainability.

- Automation and Robotics: Automating processes enhance precision and reduce energy consumption, contributing to a more sustainable production environment.

How TecTriu Supports Sustainability in Plastic Manufacturing

TecTriu supports manufacturers by helping them achieve digital transformation and eco-conscious product design through innovative approaches. Moreover, our team integrates cutting-edge technologies, like IoT and AI, to streamline operations while reducing waste and improving sustainability. This ensures positive outcomes throughout the production lifecycle.

In today’s competitive landscape, sustainability in plastic manufacturing is no longer optional but essential for long-term success. By focusing on sustainable molding processes, innovative tool designs, and leveraging advanced digital technologies, businesses can drive both environmental and economic benefits. At TecTriu, we offer tailored solutions to help businesses meet sustainability goals while enhancing their competitive edge.

The journey toward a greener future requires commitment, innovation, and collaboration across the entire industry. With this in mind, let TecTriu be your trusted partner in building a sustainable, efficient, and future-ready plastic manufacturing process.